Electronics services

A full range of services for a mature and winning industrial strategy

Electronics Services: Ensuring Product Longevity and Industrial Performance

In today’s industrial landscape, where component shortages and accelerated obsolescence are the new norm, manufacturers face growing pressure to secure production and extend the life of their products. ACTIA meets this challenge with a comprehensive range of high-value electronic services, designed to support customers throughout the entire product life cycle—from initial design to end-of-life.

With decades of experience in demanding sectors such as automotive, aerospace, rail, and energy, ACTIA provides not only robust electronic manufacturing but also strategic lifecycle management, covering obsolescence treatment, secure sourcing, and redesign.

With decades of experience in demanding sectors such as automotive, aerospace, rail, and energy, ACTIA provides not only robust electronic manufacturing but also strategic lifecycle management, covering obsolescence treatment, secure sourcing, and redesign.

A Lifecycle-Driven Industrial Approach

ACTIA’s electronic services make every stage of product development and operation more reliable. At a time when customers aim to extend the life of their systems, ACTIA helps them plan ahead, maintain availability, and avoid disruptions caused by production halts, component changes, and rising costs linked to shortages or last-minute sourcing.

This comprehensive offering supports decisions early in the development phase—especially around component choice and industrial planning—and ensures continuity throughout the entire product life cycle. It forms the basis of a mature, resilient, and cost-effective industrial strategy.

This comprehensive offering supports decisions early in the development phase—especially around component choice and industrial planning—and ensures continuity throughout the entire product life cycle. It forms the basis of a mature, resilient, and cost-effective industrial strategy.

Board Redesign for Sustainable Manufacturing

As embedded electronic systems face increasing lifecycle mismatches with their components, redesign becomes essential to ensure continuity. Through its Redesign to Deliver (R2D) program, ACTIA offers a strategic and structured approach to redesigning electronic boards.

This service typically takes place mid-product lifecycle—often five years after initial development—and aims to replace components that have become obsolete, high-risk, or difficult to source. Rather than fully redeveloping a product, ACTIA focuses on targeted, partial redesigns that reduce time-to-market, limit technical disruption, and secure long-term manufacturing.

ACTIA’s strength lies in its ability to:

This service typically takes place mid-product lifecycle—often five years after initial development—and aims to replace components that have become obsolete, high-risk, or difficult to source. Rather than fully redeveloping a product, ACTIA focuses on targeted, partial redesigns that reduce time-to-market, limit technical disruption, and secure long-term manufacturing.

ACTIA’s strength lies in its ability to:

- Evaluate BOM risk and obsolescence exposure

- Recommend alternative components or technologies

- Requalify boards after modification

- Combine redesign with supply chain resilience

This integrated redesign expertise helps manufacturers adapt to the evolving components market, mitigate supply risks, and maintain product performance—ensuring continuity, deliverability, and long-term competitiveness.

ACTIA’s Electronics Services Offering

ACTIA’s offer is structured to address every critical stage of the electronic product lifecycle with precision and added value.

Regulatory Compliance & Labeling

ACTIA supports full compliance with environmental, societal, and trade regulations, from early design to market deployment. Services include:

- RoHS, REACh, IMDS, RISL, Conflict Minerals

- Export control (ITAR/EAR), dual-use, country of origin, HT/HTS codes

Dedicated teams perform regulatory audits, advise on conformity strategies, and assist with documentation and labeling processes.

Component Management

Ensuring the right component choices is essential to building reliable and sustainable products. ACTIA offers:

- A multi-sourcing procurement strategy

- Functional characterization and qualification in real conditions

- Continuous component monitoring via the iPerSyst Component Observatory

- Evaluation of component lifecycle, supply risk, and regulatory status

This upstream effort prevents failures and aligns production with product longevity.

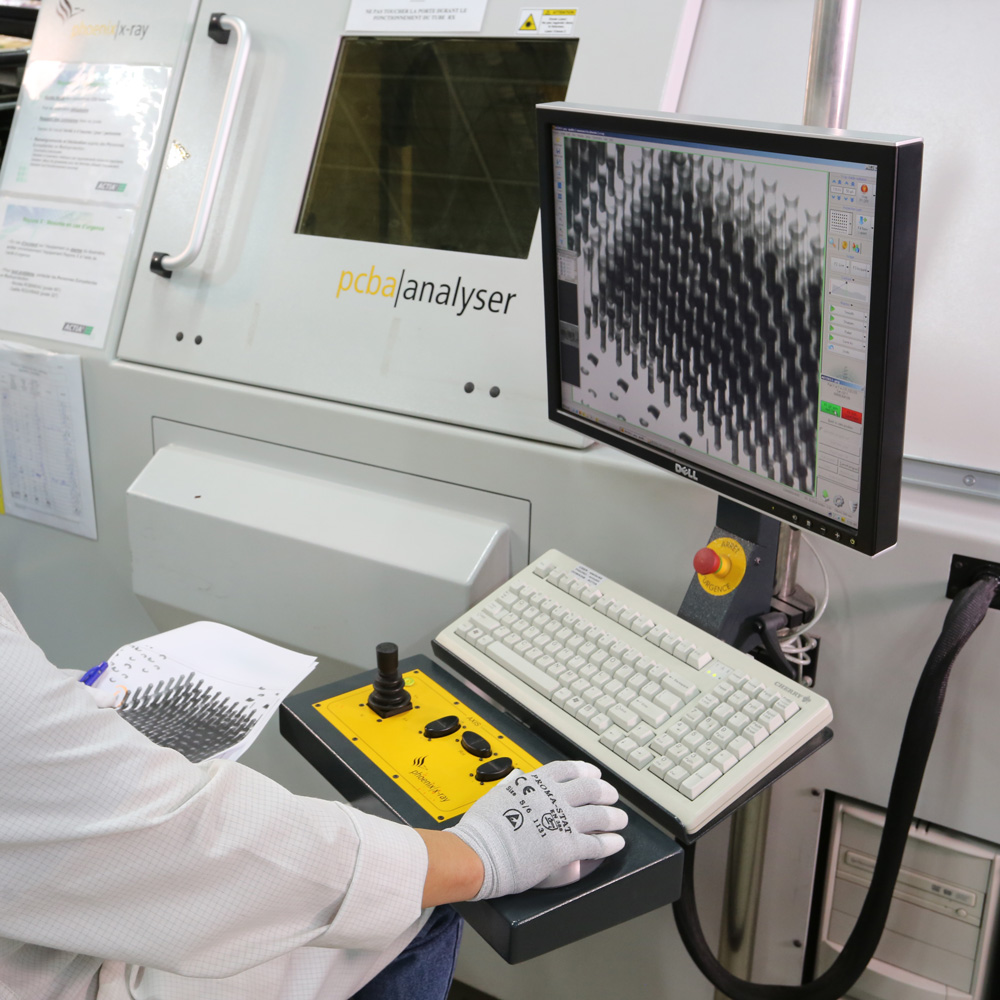

Obsolescence and Shortage Management

ACTIA’s dynamic approach includes:

- Real-time tracking of 130,000+ components and 7,500+ BOMs

- Identification and qualification of replacements or equivalents

- Redesign or cloning of components when needed

- Secure brokerage and qualification of obsolete or at-risk components

- Controlled secure storage with environmental protection and full traceability

These services ensure proactive handling of obsolescence and reduce business continuity risks.

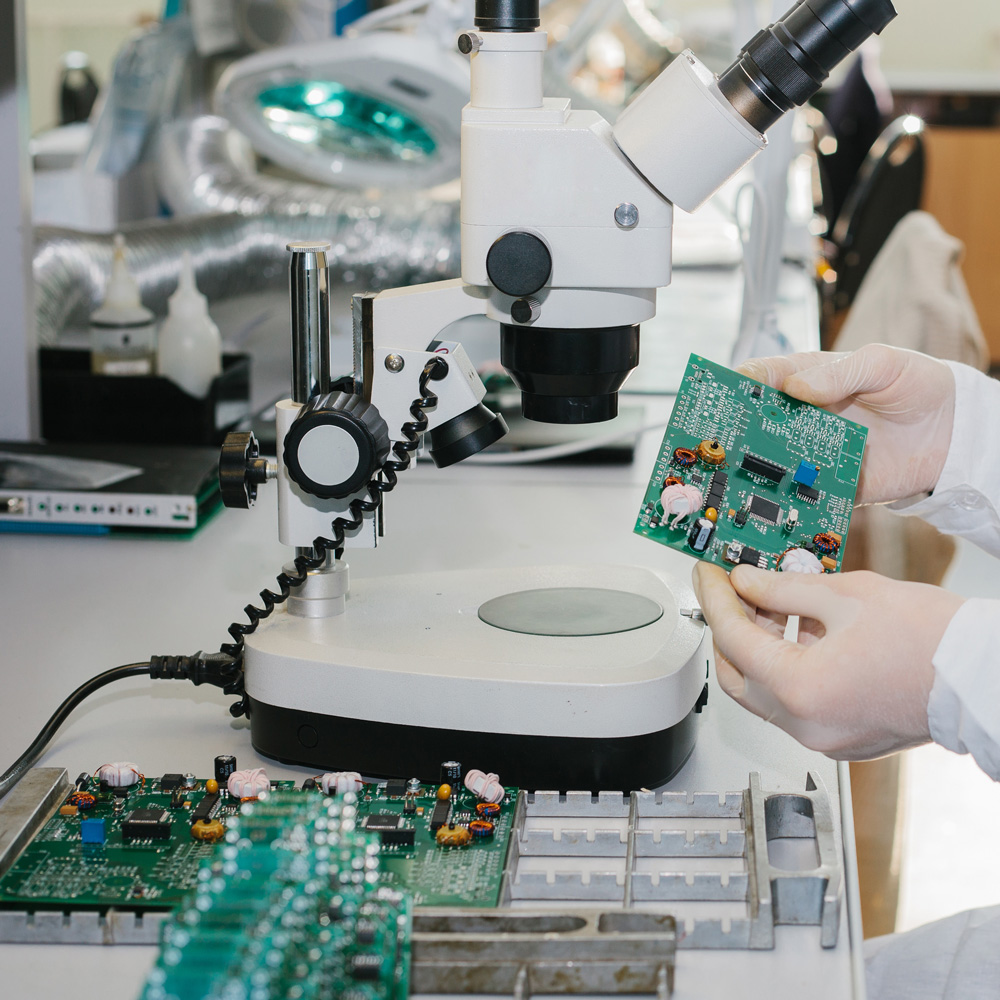

Mock-ups, Prototypes & Micro-Series

Prototype development supports industrialization by validating manufacturability and reliability before full-scale production. ACTIA offers:

- Functional validation of components in-situ

- Early DFM (Design for Manufacturing) and DFR (Design for Reliability) testing

- Prototyping with customer or ACTIA-sourced components

When required, ACTIA can perform partial redesigns to adapt prototypes to updated supply or technical conditions.

Upgrading, Repair & Logistics

Products may require functional updates or enhancements during their lifecycle. ACTIA supports this with:

- Structured upgrade programs to extend lifespan or add features

- Project-managed logistics for upgrade implementation

- A complete repair service (over 3,000 standard exchanges/year), certified to industry standards (e.g., Part 145)

This ensures long-term functionality while minimizing operational downtime.

A Trusted Partner in Electronics Continuity

Whether it’s addressing component obsolescence, adapting to shifting supply conditions, or redesigning for the future, ACTIA provides the expertise, tools, and strategic vision manufacturers need to maintain their competitiveness.

By combining engineering excellence, industrial agility, and deep market insight, ACTIA ensures that customers not only respond to today’s challenges—but are prepared for tomorrow’s.

By combining engineering excellence, industrial agility, and deep market insight, ACTIA ensures that customers not only respond to today’s challenges—but are prepared for tomorrow’s.

Looking for a complete solution from design to production?

Discover how our Manufacturing Services complement our electronics expertise to deliver performance, reliability, and industrial continuity at scale.