ACTIA Manufacturing Services

Small, medium, complex & large series production

A Legacy of Industrial Expertise

ACTIA delivers a full-range EMS (Electronic Manufacturing Services) offer, built on the Group’s longstanding expertise in the automotive industry and enhanced by its experience in similarly demanding sectors such as aerospace, rail, energy, and home automation. ACTIA’s industrial capabilities cover small to large-scale production, including complex medium series.

All manufacturing is performed within a certified industrial environment aligned with ACTIA’s commitment to sustainable development and Corporate Social Responsibility (CSR). The implementation of World Class Manufacturing (WCM) standards ensures consistent excellence across all production sites, integrating the innovations of the Factory of the Future.

Factory of the Future: A Strategic Transformation

Technology & Digitalization

Agile and Smart Organization

Skills & Human Capital

Environmental Responsibility

We are committed to reducing resource consumption, minimizing our carbon footprint, and embedding sustainable practices throughout all manufacturing processes.

Local Roots & Collaborative Ecosystems

DfX: Design That Drives Competitiveness, Performance, and Quality

We cover all key DfX domains:

- DfM – Design for Manufacturing

- DfC / DfP – Design to Cost & Procurement

- DfA – Design for Assembly

- DfT – Design for Testability

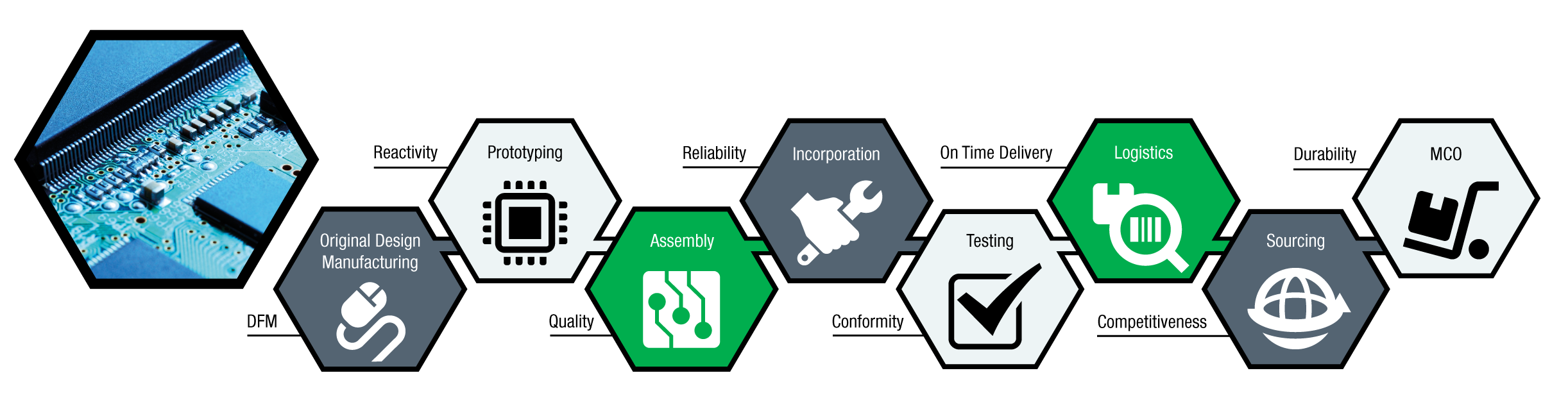

ACTIA’s Manufacturing Services Offering

- Original Design Manufacturing (ODM)

- Industrialization

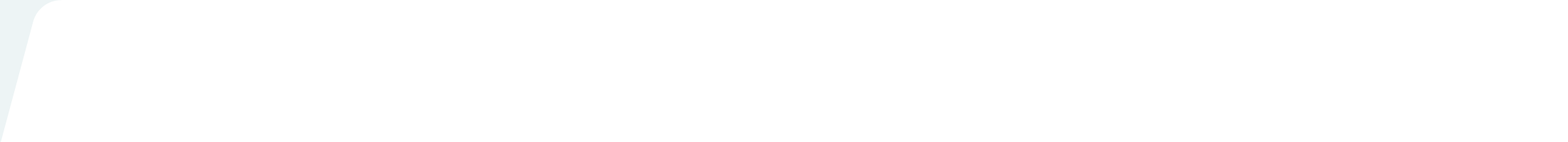

- Assembly

- Integration

- Testing & Burn-in

- Supply Chain & Logistics

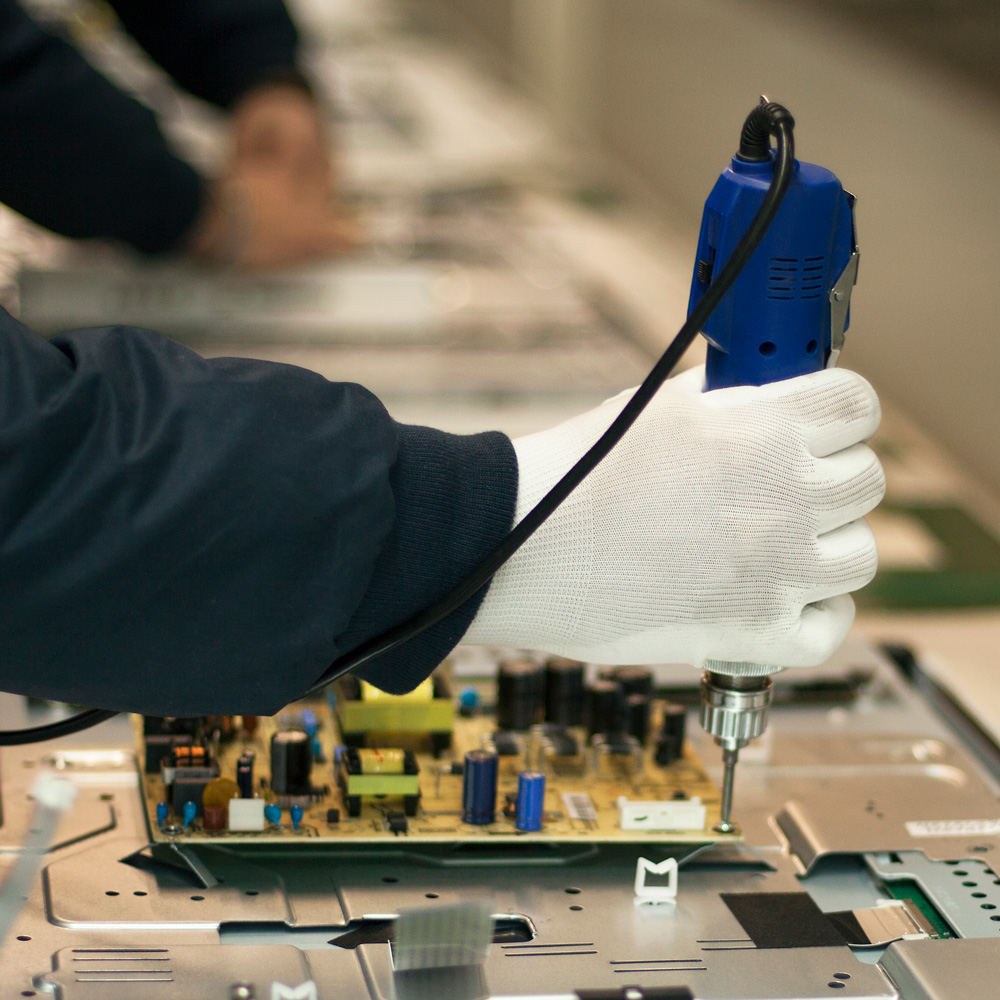

- Sourcing

Original Design Manufacturing (ODM)

Industrialization

Assembly

Integration

Testing & Burn-in

Supply Chain & Logistics

Sourcing

Advanced Testing Capabilities to Support Industrial Excellence