Global supply chains are facing unprecedented challenges, prompting many industries to reevaluate their manufacturing strategies. In this context, working with an Electronic Manufacturing Services (EMS) company in the United States is a strategic solution for businesses that prioritize resilience, innovation, and reliability. A U.S.-based EMS partner provides a competitive advantage by ensuring greater control over the supply chain, fostering closer collaboration for technical innovation, and guaranteeing adherence to the highest quality and compliance standards. This approach ensures the longevity of complex electronic systems.

The resilience of supply chains in the United States

For industries that rely on complex electronic systems, building resilient supply chains is a strategic asset. Partnering with an EMS provider in the United States mitigates the risks associated with long, fragmented supply chains. Geographical proximity drastically reduces lead times, simplifies logistics, and minimizes exposure to geopolitical and trade-related disruptions.

This localized approach provides greater control over the entire supply chain, from component sourcing to final product delivery. A U.S.-based EMS partner can closely manage the Bill Of Materials (BOM) and secure a stable supply of critical components. This is particularly crucial for sectors where product longevity and reliability are non-negotiable, such as transportation, defense, and healthcare.

For American businesses, working with a U.S.-based EMS provider fosters industrial sovereignty. It ensures that the manufacturing process is not dependent on external factors and secures a consistent supply in the long term. Proximity allows for a level of transparency and agility that is difficult to achieve with overseas partners. Manufacturers can respond quickly to market changes, production issues, or component shortages, ensuring business continuity. Prioritizing a domestic supply chain enhances operational security and contributes to a more robust and responsive local industrial ecosystem. This focus on durability and reliability is a key pillar of strategic manufacturing in the modern era.

Advanced technical expertise and quality compliance

Partnering with a U.S.-based EMS offers clear advantages in advancing technical expertise and ensuring stringent quality compliance. The domestic manufacturing sector boasts a highly skilled workforce and an unwavering commitment to industry standards. This level of expertise is essential for producing reliable electronic systems for critical markets.

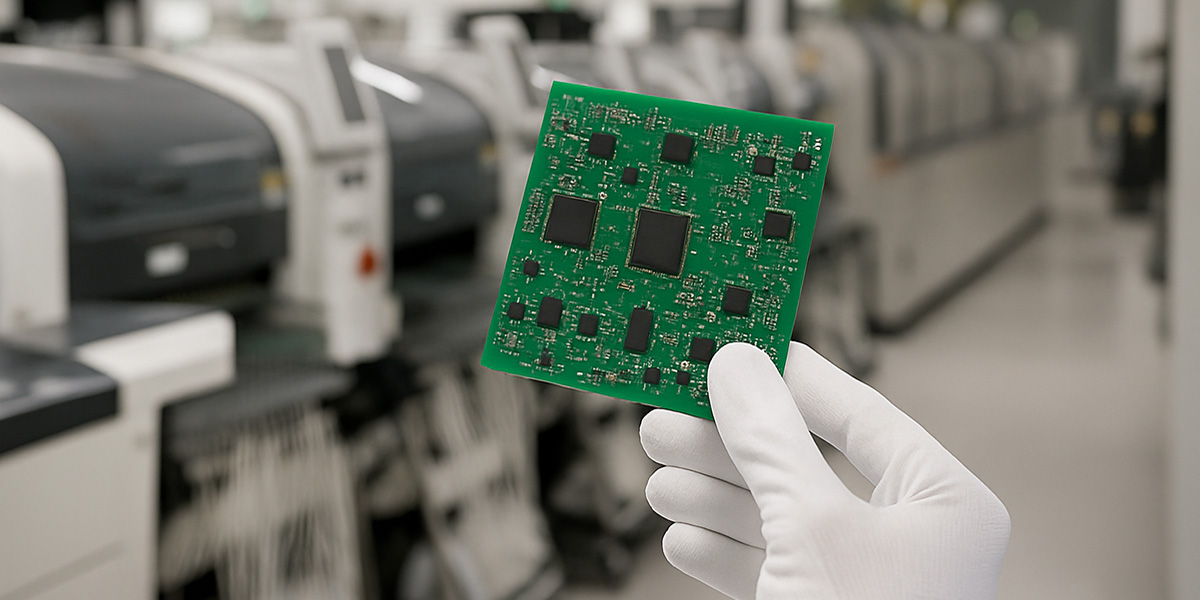

The production process itself is a testament to this technical proficiency. It begins with PCBA (Printed Circuit Board Assembly), where components are precisely placed using advanced SMT (Surface Mount Technology). After assembly, automated and manual inspections are performed. This includes AOI (Automated Optical Inspection), which uses high-resolution cameras to verify component placement and soldering accuracy. Then, electrical integrity is tested with ICT (In-Circuit Testing) to ensure that each circuit functions as designed.

Beyond these technical processes, quality is rigorously enforced through compliance with key certifications and methodologies. Partnerships with U.S.-based EMS companies often come with certifications such as IATF 16949 for the automotive sector and EN 9100 for aerospace. These certifications demonstrate a proven commitment to quality management. The Production Part Approval Process (PPAP) provides formal documentation proving that a supplier can consistently meet an organization’s engineering and quality requirements. Furthermore, manufacturers adhere to environmental directives, such as RoHS (Restriction of Hazardous Substances), to ensure that their products are safe and compliant with European Union regulations. This is a critical asset for businesses selling their products in Europe. This focus on verifiable standards and methodologies gives industrial clients confidence that their products are built to last.

Fostering innovation through collaborative proximity

North American companies benefit from innovation through collaborative proximity with a U.S.-based EMS provider. The close physical proximity of the client’s engineering team and the EMS provider’s experts enables real-time communication and the free exchange of ideas. This synergy is critical during the early design and industrialization phases.

This proximity is the cornerstone of an effective DFM (Design For Manufacturing) approach. DFM optimizes a product’s design to simplify and enhance its manufacturability, reducing costs and accelerating time to market. Rather than relying on long-distance communication and delayed feedback cycles, local teams can seamlessly collaborate to identify and resolve potential production challenges before they become costly problems.

Furthermore, this collaborative model enables a proactive approach to complex issues, such as obsolescence. The ability to quickly consult with a dedicated partner that has a specialized laboratory for managing component End Of Life (EOL) issues is invaluable. This expertise secures products with a long operational life against component discontinuation. By integrating design, manufacturing and long-term support, a U.S.-based EMS partner expands the client’s engineering and innovation capabilities, resulting in higher-quality, more durable products.

Integrated life cycle management

An EMS provider located in the United States provides an integrated approach to product life cycle management, extending from production to long-term support. This comprehensive offer is designed to ensure the longevity and sustained performance of high-reliability electronic systems. After the PCBA process is complete, the product moves to the integration stage, where electronic cards are assembled into sub-assemblies and final enclosures. Comprehensive testing is performed at this stage, with FCT (Functional Circuit Testing) verifying that the complete unit operates correctly in a simulated environment.

An American partner’s commitment to a product’s life cycle also includes logistics and long-term support. This includes the secure storage of critical components to ensure traceability and prevent degradation in controlled conditions. Furthermore, long-term support includes maintenance and repair. This support is particularly valuable for products with an extended service life in critical applications. By managing logistics, maintenance, and support, an EMS partner offers an integrated solution that secures the entire product life cycle, reinforcing durability and adaptability in an increasingly complex industrial market.

Collaborating with an EMS provider in the United States

Partnering with a U.S.-based EMS provider like ACTIA is a strategic investment in the future of electronics. This choice provides unparalleled supply chain security, accelerates innovation through close proximity and collaboration with experts, and ensures strict adherence to the highest quality and compliance standards. For industrial companies operating in demanding sectors, this model represents a competitive advantage. Leveraging local expertise allows businesses to ensure the longevity and reliability of their products, thereby reinforcing their commitment to technological excellence and industrial resilience.