In the electronics manufacturing industry, sustainable development has become a key strategic consideration. Due to the sector’s complexity, which includes a large network of component providers and manufacturers around the world, as well as a long supply chain, it is challenging for companies to reduce their environmental impact. However, given its positive impact on profitability, public image, and the environment, this is a strategic investment for industrial companies.

CSR (Corporate Social Responsibility) in manufacturing

The concept of CSR (Corporate Social Responsibility) in the electronic industry is a core strategic business aspect. It signifies a company’s dedication to ethical and sustainable practices that consider social and environmental impacts. For electronic manufacturers, it extends beyond internal operations. A CSR framework should address a wide range of issues, including ethical labor practices, employee welfare, and supply chain transparency.

Implementing a CSR policy helps build long-term resilience, enhance brand reputation and secure a competitive advantage in a market where clients and consumers increasingly prioritize responsible sourcing and manufacturing.

Human and ethical dimension

At its core, CSR is about people. It means ensuring fair wages, safe working conditions, and reasonable hours for all employees, including those of suppliers. CSR involves a strong commitment against forced or child labor, as well as promoting diversity and inclusion. For manufacturers, maintaining operational integrity and attracting top talent requires a strong ethical framework. CSR also involves active engagement with local communities, such as through educational activities or economic development programs.

Supply chain transparency

Due to the complex nature of the electronics supply chain, transparency and governance are critical aspects of CSR. This requires thoroughly vetting suppliers to ensure they adhere to ethical and environmental standards. Manufacturers must implement rigorous auditing processes to verify compliance with international labor laws and human rights standards. Transparency in the supply chain mitigates risks, provides full traceability, and assures clients that their products are manufactured under verifiable, responsible conditions.

Carbon footprint

For electronics manufacturers, measuring and reducing a product’s carbon footprint from extraction of raw materials to disposal at the end of its life is a primary challenge. This requires a comprehensive approach that considers the entire value chain, not just the manufacturing process. Understanding and addressing the carbon footprint of your products is critical to aligning with global climate goals and meeting the demand for sustainable products.

Mapping the emission landscape

A product’s carbon footprint is usually divided into three categories, or scopes.

- Scope 1 includes direct emissions from owned or controlled sources, such as on-site fuel combustion.

- Scope 2 includes indirect emissions from the generation of purchased electricity, heat, steam, etc.

- Scope 3 includes indirect emissions in the value chain, such as producing necessary components, transporting goods, and disposing of the product.

In the electronics industry, the third scope often has the most substantial impact. To achieve meaningful reductions, an effective decarbonation strategy must focus primarily on the detailed analysis and optimization of the supply chain.

Design and process optimization

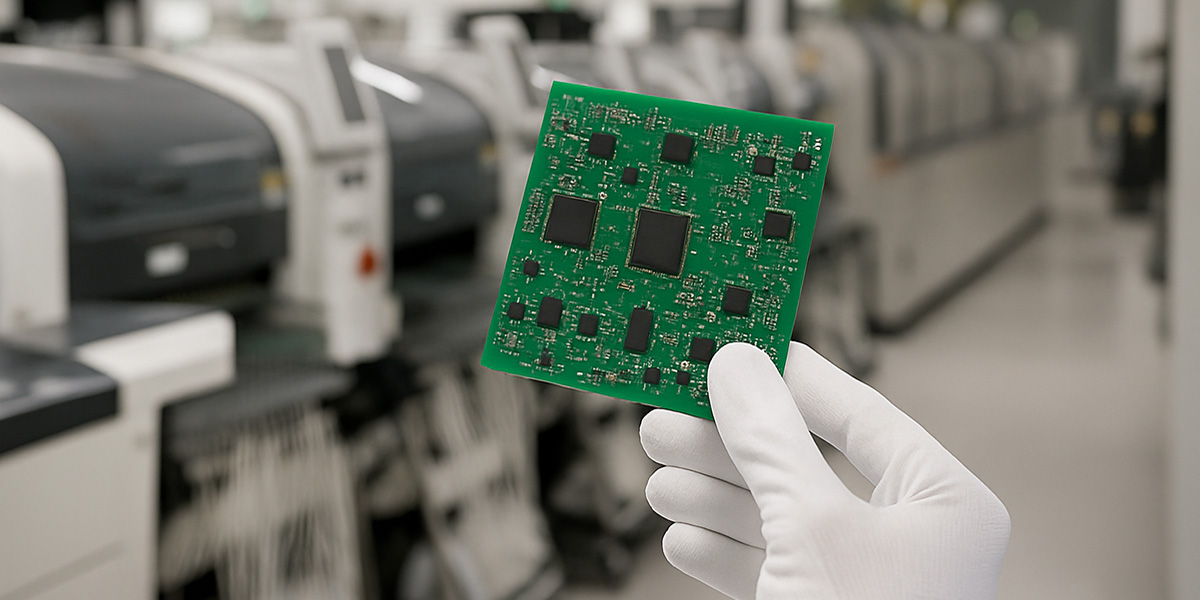

Decarbonation is deeply integrated into both operational and product design. Companies can reduce their footprint by using energy-efficient processes for Printed Circuit Board Assembly (PCBA) and Surface Mount Technology (SMT) as well as by adopting renewable energy sources for their facilities.

At the design stage, design for manufacturing and eco-design are essential. Careful selection of components and optimization of a product’s layout and materials can reduce its material consumption and energy requirements during production.

RoHS (Restriction of Hazardous Substances Directive)

The Restriction of Hazardous Substances (RoHS) Directive is a key regulatory framework that promotes sustainability in the electronics industry. Initially implemented in the European Union, the directive’s primary goal is to reduce environmental and health risks by restricting the use of specific hazardous materials in electrical and electronic equipment (EEE). Substances such as lead, mercury, and cadmium pose significant threats to the environment, especially during the end-of-life and recycling phases of a product’s lifecycle. Consequently, RoHS has become a mandatory prerequisite for market entry in the European Union and has inspired similar regulations worldwide.

Achieving compliance

Achieving RoHS compliance requires a detailed and methodical approach throughout the entire manufacturing process, from material selection to production. It is a complex technical challenge. For instance, the directive has prompted the industry to switch from tin-lead solder to a lead-free alternative, such as a tin-silver-copper alloy. This change necessitates significant adjustments to the manufacturing process, especially for printed circuit board assembly, since lead-free solders have a higher melting point.

Compliance and competitive advantage

Compliance with RoHS is a fundamental aspect of a company’s broader sustainability strategy. Manufacturers must demonstrate full traceability and adherence to these stringent standards to secure and maintain market access. Compliance also serves as a testament to a company’s commitment to product safety and environmental stewardship. Treating RoHS as an opportunity for innovation can enhance a company’s reputation, showcase its expertise, and give it a significant competitive advantage.

Why are sustainable manufacturing approaches valuable for the electronic industry ?

Successfully integrating and operating a sustainable approach requires a deep understanding of the complex relationship between a company’s actions and their broader impact. CSR, carbon footprint and RoHS compliance are not isolated concepts. Rather, they form a synergistic ecosystem. A commitment to social responsibility provides the ethical framework that motivates efforts to reduce environmental impact and comply with RoHS. Similarly, proactive efforts to lower a company’s carbon footprint often lead to operational efficiencies that directly benefit the bottom line.

Treating these elements as interdependent components enables a company to meet regulatory and market demands, unlocking new opportunities for innovation and competitive advantage. This integrated approach ensures that sustainability is embedded in corporate culture and operational processes, leading to long-term resilience and value creation.

To improve your company’s sustainability, choose an expert partner

Electronic Manufacturing Services (EMS) providers like ACTIA are essential to improving a company’s sustainability. From the earliest stages of design for manufacturing, ACTIA integrates component selection for RoHS compliance and obsolescence management to extend product lifespan. An EMS provider’s specialized expertise and processes will help you optimize your operations, reduce waste, and improve efficiency for a stronger, more resilient supply chain.