Electronic Manufacturing Sites.

A Global Industrial Group

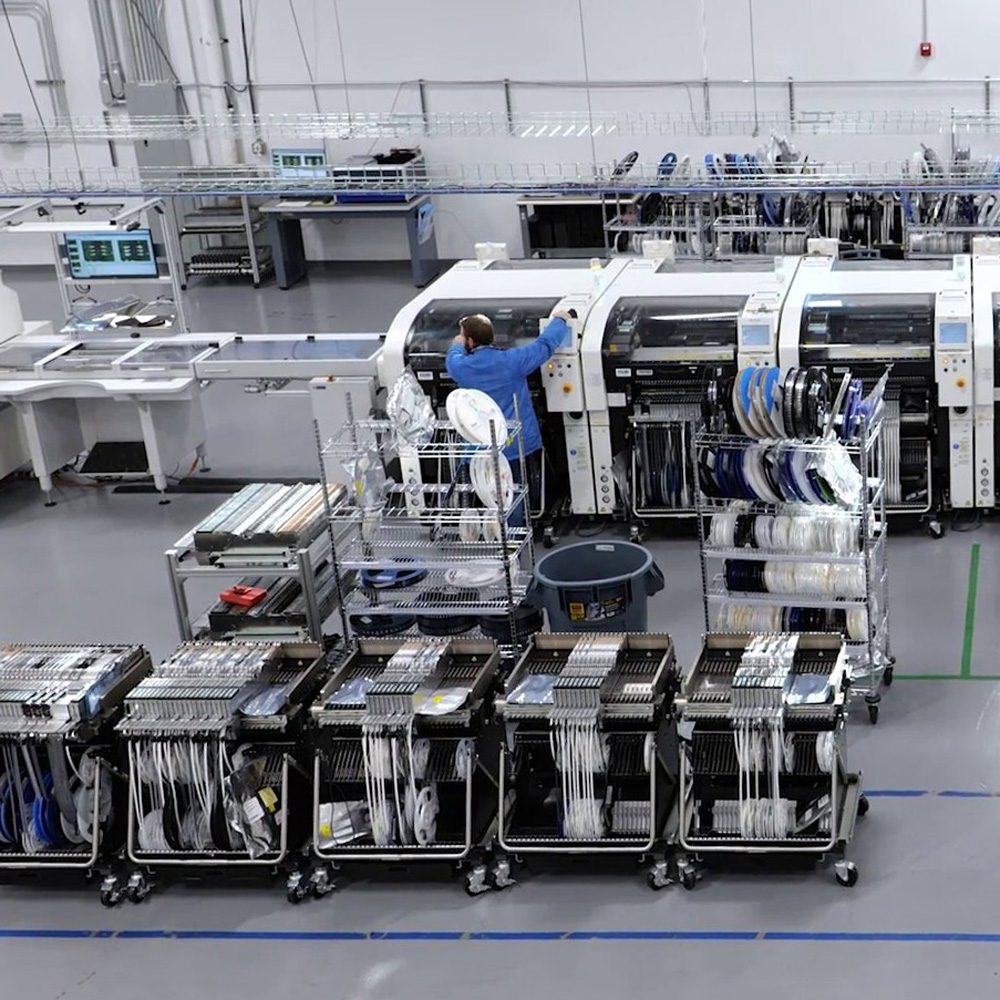

ACTIA’s factories in France, Sweden, Tunisia and the United States offer a complete range of manufacturing services in certified environments that are regularly audited by major international automotive, rail, aeronautical and space client companies.

Design for Manufacturing methods and production resources are standardized across sites, allowing for complete interoperability. In the same way, this extended operation is framed by common standards in terms of industrial performance with the World Class Manufacturing program, Corporate Social Responsibility and Cyber Security.

Teams are dedicated to modeling production resources on an international scale, and Industry 4.0 technologies are applied in a uniform manner at each site. Synergies are thus accelerated with both a pooling of tools and developments and a decentralization of the industrial management of production units as close as possible to the field and operational teams.

ACTIA’s factories combine multi-sector production capacities capable of meeting the needs of complex, small, medium and large production runs. The complementary electronic services offer micro-series production as well as prototyping and mock-up services.

The industrial organization of the ACTIA group allows each customer to implement a production strategy adapted to its volumes and to an optimal location. ACTIA accompanies over time all the industrial evolutions – Ramp Up, new markets,… – of its customers by guaranteeing the quality and the reliability of its complete offer of manufacturing services.

ACTIA Group's industrial sites

The factories located in France, Tunisia and Detroit (USA) address the group’s electronic production needs as a Tier 1 and Tier 2 supplier.

Toulouse site in france

- Employees: 350

- Finished products manufactured per year : 650 000

- Number of components per year: 0,5 Md

- m² of workshops :5.1k

Details of industrial equipment:

- 4 SMD lines including 2 large series dual line lines (ICT, selective soldering and in-line varnishing) and 2 medium series single line lines, SPI/AOI for the whole

- 2 X-rays

- 1 mixed laminar wave Lead / Lead Free

- 1 ERSA selective wave

- 1 selective varnishing line

- Integration

- Automatic troubleshooting

- 6 ICT testers including 2 with mobile probes and 4 nail beds

- Functional test

- 15 burn-in bays

- Integrated development service for functional testers

- Repair center with Part 145 approved area for aeronautical repair

Certifications:

- AE ISO 9001, IATF16949, ISO 14001, EN/AS/JISQ 9100, IRIS, ISO 27001, NADCAP

Markets served:

- Automotive, Aeronautics, Railways, Electrical Vehicle, Space

Looking for reliable electronic manufacturing in Europe?

Sites in Tunis : CIPI ACTIA & ACTIA Tunisia

- Number of employees: 542 as of 31/03/2025.

- Number of finished products manufactured per year: 3.2 million in 2024.

- Number of components per year: 683 million SMT components placed in 2024.

- Site area: 18,300 m²

Details of industrial equipment:

- 7 total SMT lines.

- 2 Dual Lane lines with selective wave soldering, in-line ICT testing, and in-line conformal coating.

- 1 Dual Lane SMT line.

- 4 Single Lane SMT lines.

- 2 lead-free selective wave soldering machines.

- 3 lead-free laminar wave soldering machines.

- 1 leaded laminar wave soldering machine (for legacy products).

- 3 automatic conformal coating lines consisting of 11 machines and 3 drying ovens.

- Laser marking of PCBs with 3 machines.

- 13 in-line PCB cleaning machines before screen printing.

- 8 in-line 3D SPI solder paste inspection machines (post screen printing).

- 2 X-ray inspection machines (sample testing).

- 24 PANASONIC SMT placement machines (homogeneous equipment fleet).

- 7 BTU reflow/polymerization ovens under nitrogen (homogeneous equipment fleet).

- 7 in-line 2D & 3D AOI SMT machines.

- 10 TERADYNE ICT testers (homogeneous equipment fleet).

- 1 UNDERFILL dispensing line.

- On-site nitrogen generation system.

- Automated Potting dispensing machine.

Certifications:

- ISO 9001:2015, IATF 16949:2016, ISO 14001:2015.

Markets served:

- Embedded electronics for all types of vehicles, consumer electronics (home automation), and power electronics.

Need scalable and cost-effective electronic manufacturing?

Site in the United States : ACTIA Electronics

- Employees : 65

- Finished products manufactured per year : 100k-120K/year

- Number of components per year : 18 million – 20 million/year

- Area: 6.000 m²

Details of industrial equipment:

- 1 Laser marking machine

- 1 SMT line , including 3D solder paste inspection and 3D automated optical inspection machine

- 1 Xray machine

- Laminar and selective wave machine , fully inert (nitrogen)

- Manual insertion and manual solder

- PCB Depaneling machines : V-Scoring and milling

- ICT Bed of nails test station.

- Flying probe test station.

- Coating line.

- Assembly and final testing area.

- Traceability and interlocking System

Certifications:

- AE ISO9001, IATF16949, ISO14001

Markets served:

- Industry, Automotive, Railway, Aeronautics Space & Defense, Energy/Smart Grid, Telecom

Seeking local electronic manufacturing in North America?

Site in Sweden

- Employees 36

- Finished products manufactured per year 120 000 (2024)

- Number of components per year 10 850 000

- Area 3000

Details of industrial equipment:

- Two new highly flexible manufacturing lines designed for minimized set up time and highest quality

Certifications:

- ISO9000/14000 and IATF

Markets served:

- Automotive, Defense, SPACE, Consumer, Industrial

Do you have an industrial project or electronic manufacturing needs?

Site in Spain: ACTIA Systems (Villaverde plant)

- Employees 10 (Incoming inspection (1), Quality control (1), SMD line operator (3), THT line operator (3), Coating line operator (1), Warehouse operator (1))

- Finished products manufactured per year : 38914 PCBAS (165 diferent models) in 2024

- Area: EMS plant

- 500 meters in 1 plant

- ESD in the entire floor

- 2 warehouses (components and finished product)

- Humidity & temperature control in all zones

Details of industrial equipment:

- Storage 2000 (europlacer)

- Printer sp710 avi(europlacer)

- Spi pi primo (mycronic)

- Pick & place ineo+ 727(europlacer)

- Oven btu (pyramax)

- Aoi (mycronic)

- Nitrogen generator (gen2 l4.0 -2130)

- Selective soldering (ersa versaflow 335)

- Soldering extractor (ersa easy arm 2)

- Takaya (apt-9411)

- Coating pva delta 6 (ab electronic device)

- Vacuum sealer (boss vakuum max 46-s)

- Depaniliser sep1/m2 (olamef)

- Visiconsult xrhcount

- Loader & unloader (europlacer)

- Loader & unloader (ab)

- Conveyor europlacer

- Conveyor ab

Certifications:

- ISO9001, ISO27001

Markets served:

- Railway and Bus & coach