Electronic components obsolescence is a constraint for all companies that manufacture, work with or import electronic systems. Over time, components may reach their End Of Life (EOL), making them difficult or impossible to procure, directly impacting production, maintenance, and product longevity. Implementing stringent obsolescence management practices is a strategic step to ensure the smooth continuation of your company’s operations.

Components obsolescence and its consequences

Effective management of electronic component obsolescence presents significant and complex challenges for manufacturers and integrators. These difficulties extend beyond the mere disappearance of components, encompassing technical, financial, and logistical hurdles that demand sophisticated strategies.

Technical hurdles in component replacement

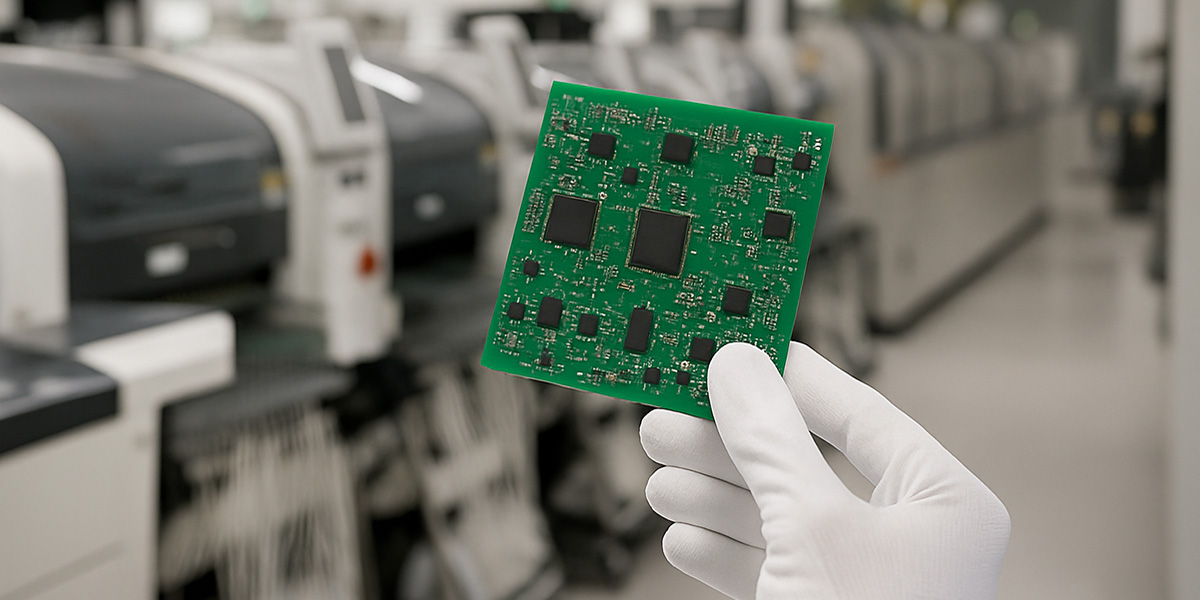

A primary challenge lies in the technical complexities of component replacement. Direct, compatible substitutes are rare and often necessitate costly redesigns of PCBAs (Printed Circuit Board Assemblies) or entire systems. Such redesigns require extensive re-validation and re-qualification processes to ensure that new components meet the original performance specifications, reliability standards and regulatory compliance. Such an effort consumes significant engineering resources and can introduce new risks if not managed meticulously.

Supply chain vulnerability

The global nature of the electronic components supply chain introduces significant vulnerabilities. Obsolescence can lead to unpredictable supply shortages, forcing reliance

on grey markets, where the authenticity and the quality of components are uncertain. Vendor discontinuations, fluctuating market prices and the need for LTBs (Last-Time Buys) add layers of logistical complexity. Furthermore, the limited availability of specialized components for older systems complicates the maintenance and repair of legacy equipment.

Financial and operational impacts of unmanaged obsolescence

The financial implications of unmanaged obsolescence are substantial. Costs accrue from emergency procurements at premium prices, extensive re-engineering, re-testing and re-certification. Unplanned production halts result in lost revenue and market share. Operationally, obsolescence can lead to longer repair time or reduced equipment availability. These factors underscore the critical need for a robust and proactive obsolescence management strategy.

What are the core constraints and challenges in obsolescence?

Organizations face many complex systemic constraints while managing obsolescence. One key challenge is the lack of standardized EOL notifications from component manufacturers. Varying last-time buys and inconsistent communication protocols can severely hamper proactive planning, forcing costly and disruptive reactive measures. Furthermore, the multi-generational nature of products in many industries means that new designs must coexist with legacy systems, each facing a unique obsolescence profile, which complicates inventory management and support strategies.

The ever-increasing complexity of modern electronic systems is another constraint. A single product may integrate thousands of components from global suppliers, creating an immense data management challenge for comprehensive obsolescence tracking. This complexity is compounded by regulatory compliance requirements, which can change and further limit available replacement options. The volume of data, coupled with the need for specialized technical expertise to assess component criticality and alternative solutions, poses an operational challenge for industries with long product life cycles.

Obsolescence management: A strategic objective

Effective obsolescence management is more than a mere operational necessity: it represents a critical strategic objective for companies engaged in electronic manufacturing, particularly given the long lifecycles of many industrial and critical systems. The primary goal is to ensure the continuous functionality and supply of

electronic systems throughout their intended lifecycle, thereby safeguarding production continuity and market commitments. This involves minimizing the disruptive impact of EOL events on manufacturing lines, product availability, and service operations.

A robust obsolescence strategy extends product lifecycles by proactively addressing challenges related to component availability. This preserves substantial initial investments in research and development, maximizing the return on existing product portfolios and ensuring the longevity of legacy equipment common in sectors such as aeronautics, automotive, energy or railways. It also seeks to control obsolescence-related costs, avoiding expensive emergency procurements, unplanned and resource-intensive redesigns, and significant financial penalties from production delays.

Ultimately, obsolescence management protects brand reputation and maintains unwavering customer trust by providing reliable product support. It also ensures long-term business resilience and competitiveness in a rapidly evolving technological landscape.

Implementing the best practices to mitigate obsolescence

Mitigating electronic component obsolescence demands a structured, proactive approach, moving beyond reactive crisis management. A fundamental practice involves the early integration of obsolescence considerations into the design phase (Design For Manufacturing, DFM). This strategy consists in:

- meticulously selecting components known for their long lifecycles,

- favoring multi-source options,

- prioritizing widely adopted standard parts to reduce reliance on single suppliers or highly specialized technologies,

- establishing clear obsolescence risk categories for all components within the Bill of Materials (BOM) to prioritize monitoring and target mitigation efforts to effectively allocate resources.

Another key element of solid obsolescence management is implementing robust lifecycle monitoring and intelligence gathering methods. It prevents your company from relying solely on official end of life notices by tracking market trends, deciphering supplier roadmaps and anticipating potential discontinuations through specialized databases and industry networks. For critical components identified as high-risk, companies should consider strategic Last-Time Buys (LTBs), carefully balancing the cost of secure storage for potential component degradation over time with the uncertainty of future demand.

Furthermore, developing a comprehensive list of pre-approved alternative components and fostering modular design principles significantly facilitates quicker and less disruptive transitions when obsolescence occurs, minimizing the need for extensive and costly redesigns.

ACTIA’s Proactive Stance on Obsolescence Management

ACTIA adopts a comprehensive and proactive approach on obsolescence management, integrating it as a core pillar of its Electronic Manufacturing Services (EMS) offer. ACTIA’s methods are distinguished by its mastery of the entire electronic production value chain from research and development to after-sales support, providing a holistic framework for long-term product sustainability. This integrated methodology ensures that obsolescence considerations are embedded at every stage of your products’s lifecycle.

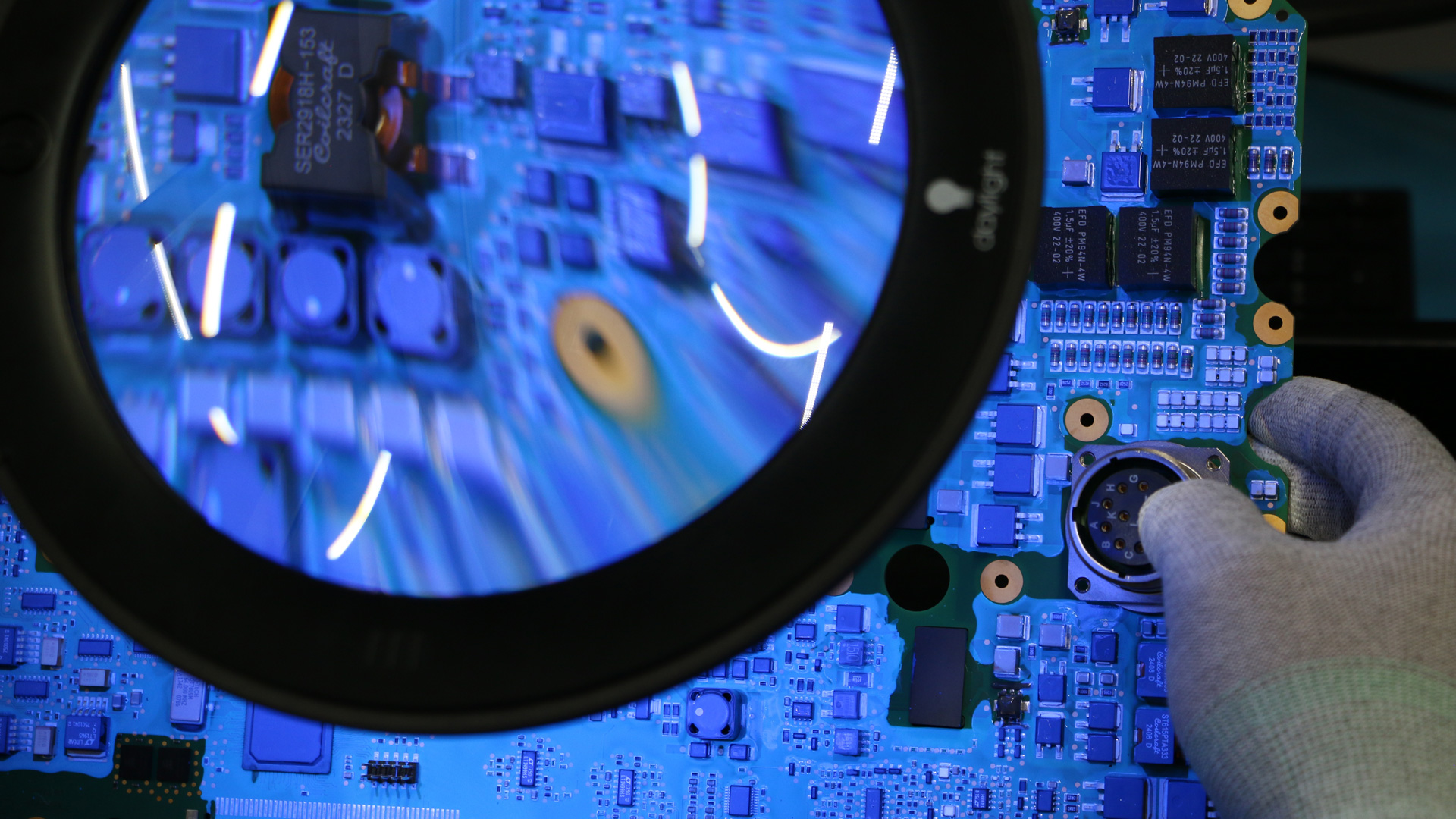

A key differentiator in ACTIA’s strategy is its dedicated obsolescence management laboratory. We are the only EMS service provider to integrate one, allowing us to better monitor component life-cycle, provide early detection of potential end of life notifications and market changes. The laboratory’s capabilities extend to developing technical recommendations for alternative components, managing preventive storage solutions for critical parts and conducting rigorous requalification and retrofit processes.

This unique in-house expertise allows ACTIA to offer concrete solutions to secure its industrial clients’ projects over the long term.

ACTIA: A partner for long-lasting electronic solutions

ACTIA dedicated its expertise to help you manage obsolescence in your organization. The quality of service will allow your company to implement robust, integrated solutions for long-term product sustainability.

Discover ACTIA’s services