Modern electronics are characterized by constantly evolving complexity. Electronics systems are becoming increasingly intricate, especially in critical sectors such as energy and transportation. The transition from conceptual design to efficient, high-volume production poses significant challenges. Design for Manufacturing (DFM) optimizes product design to facilitate streamlined, cost-effective, high-quality manufacturing processes, making it a fundamental imperative for manufacturers.

What are the core principles of design for manufacturing (DFM)?

Design for manufacturing is the systematic process of evaluating and optimizing a design for practical realization during the manufacturing process. This approach shifts the focus to a product’s manufacturability, anticipating and mitigating potential issues before they arise in physical conditions. DFM is based on multiple core principles.

- One is component selection and management: critically analyzing component technical specifications, long-term availability, cost implications and adherence to regulatory compliance such as RoHS (Restriction of Hazardous Substances). Strategic choices in this phase influence manufacturing stability and minimize the risk of component obsolescence.

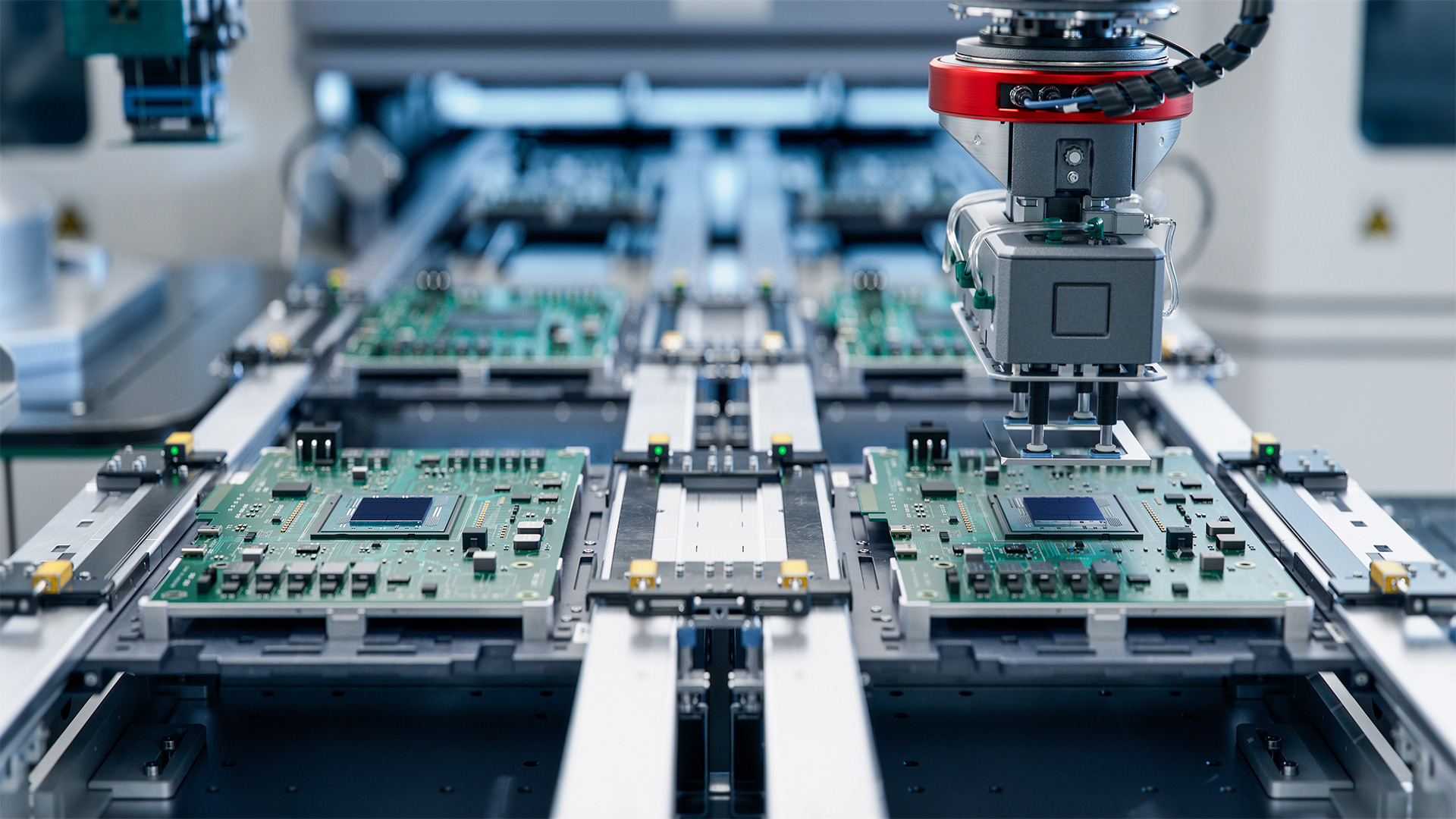

- Assembly optimization: DFM principles dictate how the design influences the efficiency of Printed Circuit Board Assembly (PCBA), through component placement for Surface Mount Technology (SMT), ensuring proper routing and defining board layouts that streamline automated processes and minimize potential assembly defects.

- Design for testability: integrating test points and strategies directly into the design phase is crucial to enable robust and efficient testing methodologies like Automated Optical Inspection (AOI), In-Circuit Test (ICT) or Functional Circuit Test (FCT).

- Manufacturing process compatibility: assessing how design choices align with specific manufacturing equipment, process flows and tooling requirements, to ensure seamless integration into production lines and maximize throughput.

- Documentation and standardization: creating a comprehensive technical documentation, including an accurate Bill of Materials (BOM) is crucial. Adherence to industry standards and certifications ensures consistent and reproducible manufacturability across production batches.

Why implementing DFM can only be achieved only within an integrated Electronic Manufacturing Services (EMS) framework?

The comprehensive benefits of Design for Manufacturing (DFM) are best realized when integrated into a complete Electronic Manufacturing Services (EMS) framework. DFM is not a standalone methodology; it is most effective when integrated into every stage of the product lifecycle, from initial design through sustainment. An integrated EMS framework provides the necessary holistic perspective and technical capabilities to effectively apply DFM during the industrialization phase.

This integration facilitates:

- Design review for manufacturability: expert teams conduct systematic analyses of designs against real-world production capabilities, identifying and mitigating potential manufacturing hurdles before they impact production.

- Process optimization recommendations: DFM expertise informs data-driven recommendations for design adjustments. These insights enhance manufacturing efficiency, reduce material waste and improve production yields by considering actual factory floor processes.

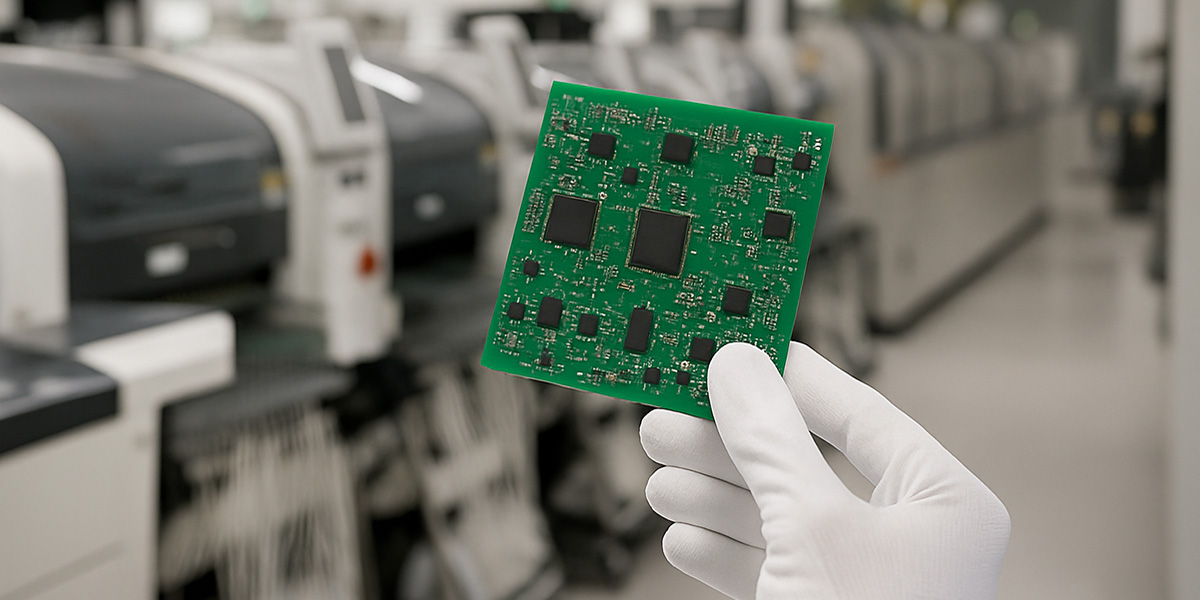

- Prototyping and validation feedback: insights derived from prototype builds and validation cycles are fed directly back into the design refinement process, ensuring that the final design is ready for mass production.

- Obsolescence management integration: DFM practices are intrinsically linked to mitigating long-term obsolescence risks. An integrated EMS provider, potentially with a dedicated laboratory can proactively manage the component lifecycle.

- Compliance and quality assurance: DFM embeds stringent quality control and regulatory compliance requirements from the outset, ensuring designs inherently support adherence to these processes and frameworks, such as PPAP (Production Part Approval Process).

Realizing operational efficiencies through DFM application

Strategically applying design for manufacturing yields significant operational efficiencies throughout the electronic product lifecycle. By incorporating manufacturability considerations at the outset of the design phase, organizations can improve production processes and overall product performance.

Production cost management is directly impacted. DFM minimizes manufacturing expenditures by reducing the need for costly rework, decreasing material scrap rates and optimizing assembly times through efficient designs. This proactive approach translates into a lower total cost of ownership for complex electronic systems.

Quality and reliability enhancements are direct outcomes of DFM, thanks to its focus on defect prevention at the source. It substantially reduces manufacturing flaws, fostering consistent products and extending their operational lifespan.

DFM also facilitates faster time-to-market by identifying and resolving potential manufacturing bottlenecks during the design phase. DFM significantly shortens development and production cycles for faster product introduction.

Designing products through DFM enhances risk mitigation by proactively addressing potential supply chain vulnerabilities, component availability issues, and technical challenges.

These methods are inherently scalable, allowing for smooth transitions from prototyping to validation to high-volume manufacturing without compromising quality or efficiency.

What is the role of design for manufacturing in long-term product sustainment and lifecycle management?

The strategic impact of DFM extends throughout the entire product lifecycle. By incorporating long-term considerations into the design process, DFM becomes a cornerstone of product sustainment.

DFM directly supports obsolescence strategy through mindful component selection and the incorporation of design flexibility. DFM practices facilitate proactive obsolescence management and enable effective retrofitting strategies when components reach their end of life. This foresight minimizes the need for costly redesigns or complete product replacement.

DFM principles also contribute to maintainability and serviceability. Designs optimized for manufacturing are often designed to be easy to repair, maintain and upgrade throughout their operational lifespan. This contributes to industrial resilience, ensuring electronic systems can perform well in demanding environments, in a comprehensive approach of EMS.

Design for manufacturing is a crucial approach for companies that want to minimize their products’ cost of ownership and maintain or improve their reputation.

ACTIA’s approach to design for manufacturing services

ACTIA offers comprehensive EMS services and applies design for manufacturing principles through its integrated research, development, and industrialization capabilities. As a recognized expert in complex electronic systems, ACTIA leverages its deep understanding of manufacturing processes and product lifecycles.

ACTIA’s DFM approach proactively identifies and resolves potential manufacturing challenges, optimizing designs for efficiency, reliability, and cost-effectiveness. ACTIA’s services bridge the gap between design intent and industrial execution, facilitating smoother production transitions and helping companies achieve stronger, more sustainable electronic product realization. This expertise is essential for businesses operating in critical sectors that require high reliability and long-term performance, including railway, energy, IoT, automotive, aeronautics or space.

Improve your manufacturing process with an expert DFM partner

ACTIA will help you improve your manufacturing efficiency through a robust DFM methodology. ACTIA’s Electronic Manufacturing Services (EMS) services will provide a comprehensive approach to maximize your production while ensuring the highest quality.

Discover ACTIA’s services