Cybersecurity: a global approach

Since 2018, ACTIA has maintained certification of its Information Security Management System (ISMS) in accordance with the ISO 27001 standard. This global approach integrates in a complementary way the application of more specific reference systems in the industrial context such as the ANSSI Industrial Cybersecurity Guide for example or Automotive cybersecurity engineering standards such as ISO/SAE 21434.

Design, develop & manufacture communication products in connected factories : the challenge of cybersecurity with several dimensions

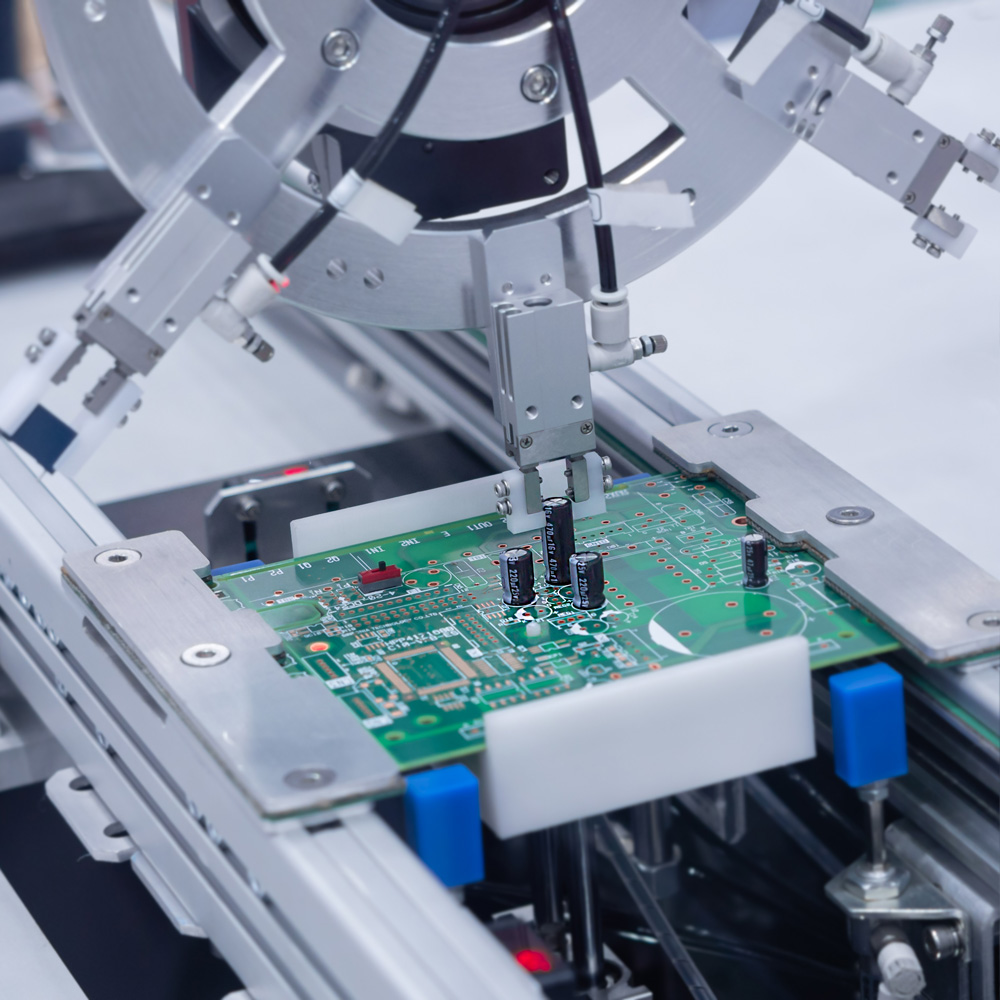

The pandemic has accelerated the digital transformation already underway for several years. Among the sectors of activity, industry is particularly affected by this transformation with the Factory of the Future. This new vision of the industrial sector opens up the possibilities with great technological reinforcement: with more automated, more connected factories, the multiplication of sensors, robots and cobots, the cloud, real-time data processing, machine learning or intelligence artificial. Technologies that give shape to the IIOT – Industrial Internet Of Things – and make the factory of the future a reality.

This development calls for another: with the proliferation of IT systems alongside OT systems (Operational Technology, industrial equipment), the industrial system is more exposed to cyber threats. ACTIA, an industrial company, took the measures of these risks by implementing a global approach and solutions to secure its entire ecosystem (infrastructure, on -board systems, personal, third -party organizations, …).

Indeed, beyond the technical security aspects of ACTIA’s production environment, meeting these challenges requires addressing cybersecurity more broadly, at the level of business processes, people, supply chains, etc.

Beyond the protection objective, ACTIA incorporates cybersecurity as a strategic axis of its development, as a pillar of its on -board systems, as a condition for the success of its factory of the future, and integrating it into the sheet on the road to its innovations.

The group has put itself into battle order to treat cybersecurity as a condition for the success of its Factory of the Future and a guarantee of the reliability of its on-board systems.

This development calls for another: with the proliferation of IT systems alongside OT systems (Operational Technology, industrial equipment), the industrial system is more exposed to cyber threats. ACTIA, an industrial company, took the measures of these risks by implementing a global approach and solutions to secure its entire ecosystem (infrastructure, on -board systems, personal, third -party organizations, …).

Indeed, beyond the technical security aspects of ACTIA’s production environment, meeting these challenges requires addressing cybersecurity more broadly, at the level of business processes, people, supply chains, etc.

Beyond the protection objective, ACTIA incorporates cybersecurity as a strategic axis of its development, as a pillar of its on -board systems, as a condition for the success of its factory of the future, and integrating it into the sheet on the road to its innovations.

The group has put itself into battle order to treat cybersecurity as a condition for the success of its Factory of the Future and a guarantee of the reliability of its on-board systems.

A 360° approach to cybersecurity

The new cybersecurity challenges in the industry are directly correlated to the evolutions linked to the Factory of the Future in a highly digitalized context and to the production of connected objects of the IOT world which integrate more and more security functions. ACTIA’s cybersecurity know-how, supported by the expertise of dedicated teams, covers a particularly wide range of applications:

- The digitization of production lines leads to a widespread use of systems from the IT world,

- The increasing interconnection and connectivity of these production lines with external environments – customer ecosystems, suppliers, etc. – are multiplying exchanges and interfaces,

- The increasing production of “smart” and connected products on the IOT market takes care of sensitive components and data, cryptographic keys, …

- The operation of ACTIA’s factories as extended industrial tools implies permanent connections and exchanges at all stages of the manufacturing and supply chain.

Present everywhere, cybersecurity issues are managed by ACTIA with a holistic 360° approach including the production environment and more broadly the business processes and human skills. The human dimension is a fundamental part of the system and the teams involved in the entire industrial process are trained in risks and their management..

A structured approach : from anticipation to resilience

The implementation of the cybersecurity strategy within the ACTIA Group’s plants is based on 4 pillars:

- The digitization of production lines leads to a widespread use of systems from the IT world,

- The increasing interconnection and connectivity of these production lines with external environments – customer ecosystems, suppliers, etc. – are multiplying exchanges and interfaces,

- The increasing production of “smart” and connected products on the IOT market takes care of sensitive components and data, cryptographic keys, …

- The operation of ACTIA’s factories as extended industrial tools implies permanent connections and exchanges at all stages of the manufacturing and supply chain.

Since 2018, ACTIA has maintained certification of its ISMS information security management system in accordance with the ISO27001 standard.

Ready to Secure Your Industrial Future?

Our experts are here to support your cybersecurity journey.